|

|

E-News Update September 2010 |

LEAD FEATURE |

K2010 NEWS |

COMPANY NEWS |

MATERIALS NEWS |

MACHINERY NEWS |

EXHIBITION NEWS |

RUBBER JOURNAL ASIA |

INJECTION MOULDING ASIA |

![]() Injection Moulding Asia

Injection Moulding Asia

|

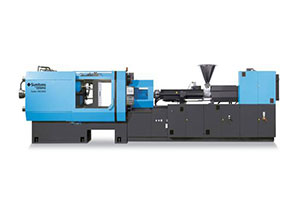

Sumitomo expands hydraulic machine size

Sumitomo (SHI) Demag has expanded its Systec hydraulic injection moulding machine to offer tonnages from 25 tonnes to a maximum of 1,000 tonnes.

For machines with clamping forces of 130 to 1,000 tonnes, the toggle drive on the clamping unit brings about further reductions in power requirements as compared to other all-hydraulic clamping systems, says the company. It also features a sturdy and compact design but with clearance for large moulds. The guidance of the mobile mould plate allows for highly precise clamping movements, thus reducing mould wear. In addition, the activeQ mould protection feature detects malfunctions across the freely definable mould protection area and does not increase the cycle time, says SHI.

The company says the machine is characterised by short cycle times and high levels of precision or availability to facilitate efficiency while offering cost-benefit ratios. Another factor enabling low costs of operation is the independent cooling circuit (activeCool+Clean) that facilitates oil lifetimes of 40,000 hours.

Modular injection units, various configuration levels and a comprehensive package of optional features make the Systec a flexible machine. The modular design of this machine is also reflected by the machine control of the Systec since all machines in this series come with the ergonomic NC5 control.