Emery Oleochemicals introduces new portfolio of additives for C-PVC

Also, download this story from the electronic issue here

Emery Oleochemicals, a global speciality chemical manufacturer, has developed a portfolio of additives for chlorinated polyvinyl chloride (C-PVC).

C-PVC is significantly more flexible and withstands higher temperatures than standard PVC. While standard PVC loses its form stability at temperatures of 60 to 80°C, C-PVC can withstand temperatures up to 100 to 120°C.

C-PVC is also significantly more ductile and fracture-resistant than PVC, which makes it suitable to replace corrosive metal piping systems. Therefore, producers of tubes and fittings for hot and cold water distribution prefer to use C-PVC.

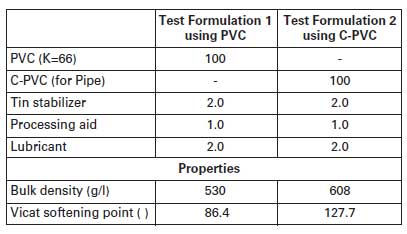

Table 1: Comparison of density and thermal resistance using PVC and C-PVC

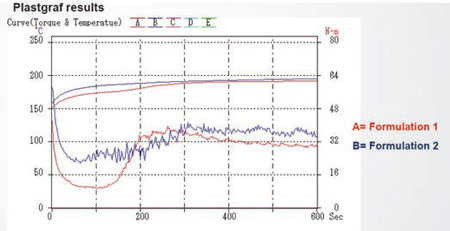

Figure 1: Plastgraf results. Red line (Formulation 1) is based on PVC; Blue line (Formulation 2) is based on C-PVC

Additives necessary to process C-PVC

Just as for standard PVC, additives are necessary

to process C-PVC. However, additives specifically

designed for C-PVC can preserve and even improve

the desired properties of this material.

the desired properties of this material.

To preserve a high heat resistance, it is essential to choose additives that do not influence the Vicat softening point. At the same time, friction must be reduced to improve the processability of the polymer melt.

Consequently, a higher dosage of external lubricant improves the processability without reducing the Vicat softening point. While the static heat stability of C-PVC is similar to standard PVC, the dynamic heat stability can be significantly improved using LOXIOL® 2307 (Figure 2).

Figure 2: LOXIOL® 2307 (right image) improves dynamic heat stability better than standard lubricant (left image)

To meet the market’s unique requirements, Emery Oleochemicals has developed a broad product portfolio specifically for C-PVC applications.

LOXIOL® 2307, an external lubricant, has a high dropping point of 80°C to 90°C, which improves the handling of the product. It is thermal stable in a wide temperature range.

LOXIOL® 2307 is suited for extrusion of rigid PVC and C-PVC pipes, window profiles, fittings in tin, calcium/zinc, and calcium-organic stabilised formulations. It improves the plate-out behaviour and therefore, reduces the cleaning cycle time. With this external lubricant, the fusion time can be adjusted and it also improves the dynamic heat stability.

By adding oxidised PE-wax, the dynamic heat stability of the compound can be increased. LOXIOL® 2307 has no impact on the colour of the final product. Therefore, it is ideally suited for white products. Furthermore, it improves the surface properties of the end product.

For some applications, additives with both internal and external lubricating effects might be required.

LOXIOL® 2308 is a neutral ester wax that suits this purpose. It improves the flow properties of the polymer melt and prevents it from sticking to the mould surface.

LOXIOL® 2308 has food contact approval making it well suited for residential water supply systems.

As a mould release agent, LOXIOL® 2309 is a useful supplement, especially for injection moulding of fittings. Using both of these additives increases the productivity and reduces the cost for additional cleaning cycles.

LOXIOL® 2310 is a lubricant developed to prevent plate-out tendency and to reduce the adhesiveness of the polymer melt. It has a high dropping point which improves the handling of the product. Even at small dosages of 0.2 to 0.3 phr, it reduces the time for cleaning cycles, which leads to considerable cost savings. In combination with LOXIOL® 2307, best results for an optimal rheological behaviour and minimal plate out can be achieved.

Emery Oleochemicals has decades of expertise with C-PVC applications. In close collaboration with our business partners in Japan, we have developed product solutions that guarantee the optimal result for various application areas.

In addition to additives for C-PVC, Emery Oleochemicals’ Green Polymer Additives business unit manufactures a wide range of standardised products as well as customised solutions including lubricants, plasticisers, viscosity depressants, antistatic and antifogging agents as well as release agents made from renewable resources.

As a part of the polymer formulation, these additives enable or optimise the production process while also improving the properties of the final plastics part. Our LOXIOL®, EDENOL® and EMEROX® brands stand for high quality and reliable products for the plastics industry.

Our Global Technical Development Centre located in Loxstedt, Germany, supported by our regional Product & Application Development laboratories in North America and Asia, allows us to engage in joint product development efforts with our customers on a global scale and offer exceptional technical support worldwide.

You may also visit us at Chinaplas 2017, the 31st international exhibition on plastics and rubber industries, being held at Guangzhou, China, from May 16th-19th. Our Green Polymer Additives team is looking forward to meeting you at booth C01 in Hall 10.2.

Contact Emery Oleochemicals's’ technical experts to select the best suited additive for your application at gp.asia@emeryoleo.com.

About Emery Oleochemicals Group

Emery Oleochemicals Group is a leading producer of natural-based chemicals made predominantly from natural oils and fats such as plant-based oil and tallow. We offer an extensive product portfolio, including renewable solutions for the Agro Green, Bio-Lubricants, Eco-Friendly Polyols, Green Polymer Additives, Home & Personal Wellness and OleoBasics markets.

With revenue of US$700 million (2015), the company is headquartered in Malaysia and has manufacturing plants and Technical Development Centres spanning three continents in North America, Europe and Asia Pacific.

Emery Oleochemicals’ global operations are supported by a diverse workforce and an extensive global distribution network covering over 50 countries worldwide. For more information, visit www.emeryoleo.com.

(PRA)Copyright (c) 2017 www.plasticsandrubberasia.com. All rights reserved.