PolyAd and Tosaf introduce new additives for nylon and PC

Israel's Tosaf has added to its portfolio two new masterbatches that have been developed to modify polycarbonate (PC) for applications such as multi-wall and solid sheets for construction and other applications. FR7607PC increases flame retardancy even at low sheet gauges, whilst IR5980PC provides an increased IR selective effect and thus acts as a highly effective heat reduction masterbatch.

LDR (let-down ratio) values of 5 % to 7 % of the new flame retardant additive FR7607PC are sufficiently low to achieve a UL94 V-0 classification at 1.6 mm, whereas PC modified with Tosaf’s established multi-purpose grade FR3997PC only meets the same specifications at 2 mm and above. For applications in the construction industry, this means that current fire retardancy standards can now be met with even thinner and lighter PC sheets. At the same time, FR7607PC can pave the way to lower wall thickness injection moulded parts for electric and electronic applications.

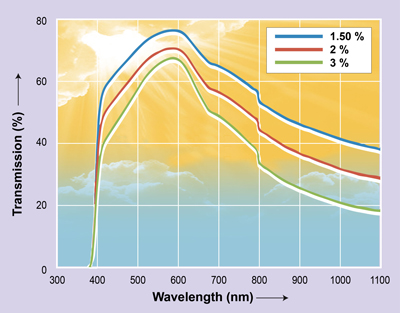

IR5980PC is Tosaf’s new, highly effective cooling masterbatch, which has likewise been developed mainly for PC applications such as lightweight construction sheets. At a rate of addition of 1 % to 6 %, this new near IR selective masterbatch filters out a significant proportion of near IR (NIR) radiation in the 700 nm to 1500 nm range and thus helps to prevent interior spaces from heating up excessively. Masterbatch levels of as low as just 3 % provide a good CF (Cooling Factor) value of 1.17(*). The CF value reflects the correlation between transparency to visible light and SHGC: at CF<1, a material allows more heat than light to pass through, whilst at CF>1 more light than heat can pass through. PC sheets containing this masterbatch maintain their high transparency to visible light with a light greenish undertone. IR5980PC can be directly added to PC granules in the extrusion process or coextruded as separate layer.

PolyAd's new additives for nylons

PolyAd Services, headquartered in the US, is introducing two branded product lines to drive enhanced performance and efficiency of light-weight nylon, especially for end-users in the automotive, fibre, wire and cable industries.

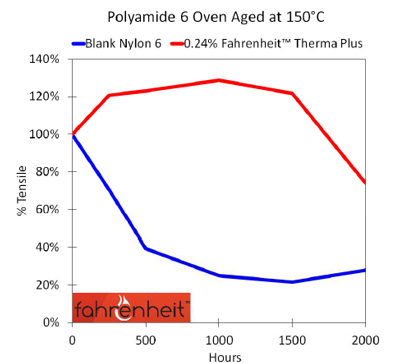

The new PolyAd Fahrenheit series enables high temperature thermal stability for the most demanding applications, including under-the-hood automotive uses such as intake manifolds, radiator components and transmission elements.

The Fahrenheit series includes eight separate products, each offering different specific benefits to customers and end-users in the automotive exterior, interior and tyre cord industries and also in the fibres, wire, cable and electrical applications.

The new PolyAd Epoch|UV series creates long-term light stability and pushes results into what previously had been considered unattainable levels of colour and gloss retention for outdoor products and carpet fibres. This series includes five separate products with different applications in the automotive interior, automotive exterior, electrical, fibre, wire, cable and film industries.

(PRA)Copyright (c) 2016 www.plasticsandrubberasia.com. All rights reserved.