Having shown the technology at the K2013 last year, machinery maker Reifenhäuser Kiefel Extrusion says the Evolution Ultra Fusion, the first direct extrusion technology for the production of multi-layer blown films, is now being further developed for commercial use. The German firm says that tests conducted under production-oriented conditions in its technology centre confirm the “competitive advantages” initially presented at K2013

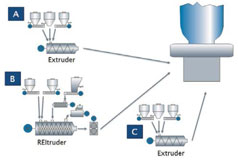

The technology processes raw materials directly – without previous pre-drying and compounding. For this reason, the engineers came up with the concept of integrating a twin-screw extruder of the REItruder series directly in a blown film line. Compared with the processing of compounds and masterbaches, the direct extrusion technology can reduce the production costs for three-layer blown films by more than 15%, says the company.

The technology shows its full savings potential particularly in the production of filled multi-layer films in which expensive raw materials like polyethylene, are replaced in part with lower-priced fillers such as calcium carbonate. The technology also enables producers to process especially high filling amounts of up to 50%, thus reducing their production costs by about 20%.

In addition to cost savings, the high filling amounts have a positive effect on the film properties: Film strength and film stiffness are increased while elongation is reduced. Furthermore, special properties can be obtained with this technology, for example those needed for the production of breathable films.

Together with a partner from the industry, Reifenhäuser Kiefel Extrusion is developing products for industrial use to bring the technology to the market.

The line is targeted for the production of nonwovens, films and wood polymer composites and is available for testing at the company’s site in Troisdorf.

Examples of applications include:

- Packaging bags for flower soil and peat

- Compression bag film

- Breathable and non-breathable diaper backsheets

- Breathable film

- Bio film, for example PLA plus filler