Canada-based Macro Engineering & Technology says its new high speed coextrusion line for producing biaxially-oriented (biax) sausage casings can produce structures up to 11 layers using nylon, PE and EVOH. It can also be extended to allow processing of structures with PVdC. It produces casings with width calibres of 80 to 120 mm and thickness ranging from 40-50 microns. The line operates at speeds up to 170 m/minute.

The firm also says that in line with its commitment to innovate machine design that provides versatility to the processor, the line can be readily converted to produce films for barrier shrink bag production.

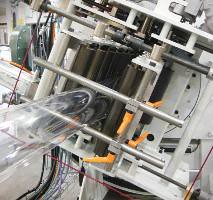

The line includes a primary bubble forming section with a vacuum calibrator, orientation section with infrared (IR) sectional heaters and an IR annealing oven. The bubble diameters in each section are precisely measured and controlled to ensure consistent production quality. Operation of the line is complex so Macro has incorporated an advanced control system to assist operators. The control system contains recipes for automatic ramping up (and down) of the line speed with simultaneous adjustment up to 30 process parameters.

Macro intends to add automatic gauge control to the system by 2015.

(PRA)