New packaging technologies and food safety

Also, download this story from the electronic issue here

We eat to live, so we choose to eat what we believe is safe and clean. Can the new packaging technologies, like active and intelligent packaging technologies, meet consumers need for food safety, asks Angelica Buan in this report.

Food safety is a global health issue, says the World Health Organisation (WHO), which estimated that one in ten people or 600 million people around the world are affected with food-borne illness, particularly from contaminated food.

In the US alone, health authorities lose nearly US$16 billion a year to food contamination. In fact, a 2015 study by an Ohio State University Professor estimated that sufferers from food contamination incur losses totalling US$55.5 billion.

Southeast Asia posts an alarming rate of food contamination mortality: it has been reported that some 175,000 people die from food contamination a year, citing latest WHO data on the region.

WHO Regional Director for Southeast Asia, Poonam Khetrapal Singh, stated that hygiene, adequate food production and storage conditions, to mention a few, are challenging parameters for the low and middle income sectors, further suggesting that food safety must be considered a public health priority.

Indeed, the region is beginning to tackle food safety concerns. Malaysia recently launched the Asean Risk Assessment Centre for Food Safety. It aims to be a regional coordinating centre for independent food safety risk assessment, and will also formulate scientific opinions and provide advice on the safety of food. It will contribute to the enhancement of the health of the ASEAN Community and facilitate its food trade, says the country’s Health Ministry.

China is clearing its image as having low standards of food safety and has come up with a new food safety law – dubbed as the strictest of known food safety laws. It took effect 1 October 2015. The law underscores the implementation of technologies such as detection, traceability and anti-counterfeiting to establish food quality system.

In Thailand, the Ministry of Public Health-led Food Act B.E. 2522 safeguards consumers against foodrelated health hazards with labelling, food production and import control, registration of food operations and approval of packaging materials, to cite a few of the provisions. Moreover, organisations are taking an active role in implementing food control measures.

Vietnam is also battling with food safety concerns. Reports say that the consumption of organically grown food is a growing trend, to avoid chemical-laced produce.

Recipe for recall

Food products manufacturers and processors who are found to violate food standards face fines or recalls. The last thing that a company wants is to be faced by costs of the recall, lost sales, brand damage and customer loyalty.

Recently, US food manufacturer Bumble Bee Foods had to execute a voluntary recall. It had to pull off the shelves 31,000 cases of its canned tuna, suspected to be processed by a facility not owned or operated by the company, and thus, the tuna faced possible spoilage from bacteria that could pose life-threatening illnesses if consumed.

This incident highlights the role of processing technology in combatting food contamination caused by the presence of pathogenic organisms, notably from poorly processed foods.

The Europe Food Safety Authority (EFSA) notes that a rising number of human health cases and deaths are linked to infections from organisms like salmonella, often transmitted in eggs or poultry, and listeriosis from dairy products, fruits, vegetables and seafood.

On the other hand, processed food made for children is subject to heavy scrutiny by consumers and food safety regulators. Of the segments that are affected by food contamination, WHO says that the under-five yearold children pose as a high risk group. The WHO data for Southeast Asia revealed that three in every ten children are affected by food borne illnesses. Globally, this age group accounts for 125,000 deaths every year from food contamination, WHO said.

Thus, alerted by possible food spoilage following consumer complaints, Switzerland-headquartered Nestlé’s baby food maker Gerber Products Company issued a recall for two of its flavours of the Organic 2nd Food products that might spoil prematurely.

Packing in food safety

Fresh foods are now competing with packaged, readyto- eat-foods, not only in terms of convenience but also in the assurance that packaging provides a level of safety not satisfied by manual storing and handling.

Nevertheless, packaged food manufacturers have to juggle between ensuring safety and freshness of the product, yet allowing for minimal processing, according to EFSA. Techniques such as freezing, canning and chemical preservatives may ensure safety and longer shelf-life that also carries the caveat of compromising quality of texture and taste.

These techniques are winning only half the battle against food spoilage, since regular food containers that offer poor barrier protection can also promote microorganism growth.

Science-based organisation Food Standard Australia New Zealand (FSANZ) states that food packaging can prevent contamination, allow food to be transported easily and extend shelf life. Thus, packaging plays an important part in providing safe food to consumers.

One of packaging’s vital purposes is to protect the product inside it against unsuitable conditions like exposure to light, humidity, temperature, oxygen and heat as well as migration of substances; and thus ensure safe consumption. Packaging also provides a surface for labelling and product differentiation.

With technologies in place and the heightened regard for food safety, food packaging has transfigured from mere containers to hold or keep food into active packaging that provides barrier from oxidation, moisture and keeping in flavour, according to a study on packaging innovations published online in the Agricultural and Food Chemistry journal.

Currently, active and intelligent packaging systems are the latest innovations that ensure food quality. While these innovative packaging systems present exciting opportunities for food manufacturers and processors to meet consumer requirements for food safety, regulations for these packaging types are yet to be cemented.

According to a report: New EU regulation aspects and global market of active and intelligent packaging for food industry applications, Regulation 450/2009/EC (preceded by Regulation 1935/2004/EC) has been set to stand as a legal basis for the correct use, safety and marketing of these new packaging types. However, since these are food-contact packaging, they are subject to stringent regulatory standards and some observers suggest the possibility of substance migration.

Citing information from EFSA, the organisation says that safety of food contact materials requires evaluation as “chemicals can migrate from these materials into food”. It emphasises the need for strict compliance to the EU regulations in manufacturing these materials, as well as following good manufacturing practices, “so that any potential transfer to foods does not raise safety concerns, change the composition of the food in an unacceptable way or have adverse effects on quality.”

Active packaging: modifying the gas environment

Active packaging has substances such as oxygen absorbers and antimicrobials included in or as the packaging material or the package headspace to enhance the performance of the package system.

The so-called active packaging uses special packaging material that interacts with the internal gas environment to prevent spoilages. The technology modifies the gas environment inside the product packaging, and thus steps up the basic protection function of regular packaging versus oxygen and moisture, which are the main culprits that cause food to spoil.

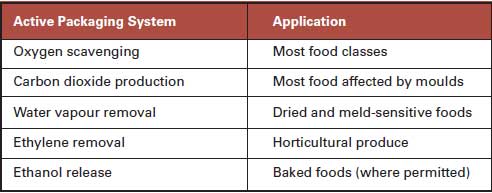

Research firm Transparency Market Research cites

some of the methods in active packaging including oxygen scavenging, ethylene scavenging, ethanol release, carbon dioxide release and water vapour removal. It explains that these barrier enhancements aid in products such as fresh farm produce and poultry, which are biologically active when packed in flexible packaging materials.

Certain gases are released due to metabolism and tend to accumulate within the headspace of the packaged food item. The accumulated gases cause the deterioration of the packaged food. In this case, for example, the scavengers used in the active packaging absorb these gases and liquids accumulated within the headspace of the packaged materials.

Active packaging is relatively new in Asia Pacific, TMR states, implying also that the costs are the main factor in limiting demand in the region. However, it said that technological advances could ease costs and encourage demand.

Meanwhile, a biobased, chemical-additive free packaging film with antimicrobial and antifungal properties has been developed by researchers from the National University of Singapore (NUS). The team says that the chitosan, sugar derived from shells of crustaceans, doubles the shelf-life of food.

The chitosan-based composite film, which inherently has antimicrobial and antifungal properties, is blended with grapefruit seed extract (GFSE), which possesses antiseptic and germicidal properties, to further slowdown fungal growth of packaged food, Additionally, the composite film also bars ultraviolet light, thus preventing food spoilage from oxidation.

Intelligent Packaging: no headspace for spoilage

As for intelligent packaging, UK firm Smithers Pira in its report, The Future of Smart Packaging to 2021, said that it enhances the communication function of traditional packaging, and communicates information to the consumer based on its ability to sense, detect, or record external or internal changes in the product's environment.

Intelligent packaging uses time-temperature monitors, smartphoneenabled interactive labels and radio-frequency identification (RFID) tag, as well as nanomaterials and biosensors to detect the accumulation of gases within packaged food items and is expected to make headwinds in the near future.

Embarking on the potentials of intelligent packaging market, the VTT Technical Research Centre of Finland has developed a sensor that detects ethanol, which forms when food is deteriorating, in the headspace of a food package. A signal from the sensor is emitted and read wirelessly via an RFID reader on a mobile phone.

Meanwhile, researchers from the Indiana University of Pennsylvania created a microchip that detects food spoilage. The patented chip is made up of a chemical element antimony and a layer of cobalt that scatters into nanoparticles, with thickness of about 20 atoms. The thin device, attached to food product containers when packaged, can work as time-temperature indicator. The chip sends shelf-life data to smartphones or like devices.

These innovative packaging systems are now gaining momentum among consumers. Smithers Pira reported that the market is ready for active and intelligent packaging technologies; and this readiness translates to a growth forecast of US$7.6 billion for global smart packaging market within a five-year period to 2021.

However, the high cost of producing active and intelligent packaging continues to impede their demand potentials, since cost-competitiveness remains a key consideration among food manufacturers and retail industry players.

(PRA)Copyright (c) 2016 www.plasticsandrubberasia.com. All rights reserved.